UAP, the specialist in locks and hardware for doors and windows, has launched a new scheme to proactively improve sustainability across the business.

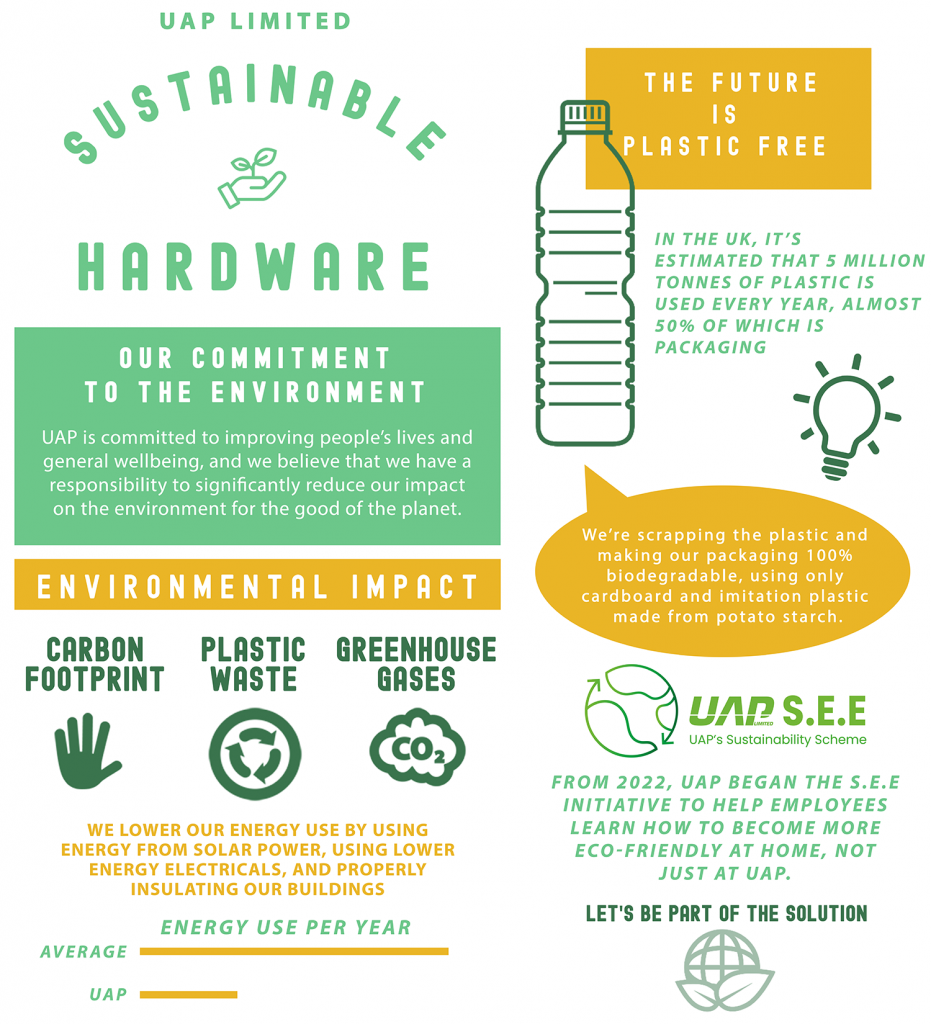

The initiative considers the social, economic and environmental (S.E.E) factors that must be addressed by UAP to drive positive change. Designed to engage employees at all levels, every department is tasked with developing new ideas and practices that can make a tangible difference.

“Our aim is to go above and beyond what is required by accreditations such as ISO:14001,” explained David Jennings, CEO of UAP. “That’s why, unlike many other sustainability initiatives, our S.E.E. scheme doesn’t just focus on minimising our environmental impact. We also want to identify opportunities for creating social value in our local communities and continue to drive efficiencies to ensure UAP remains a sustainable business.

“This will make sure that we approach sustainability more holistically and develop commercially viably ideas focused on generating long-term benefits.”

As part of the campaign, sustainability champions have been appointed in each department to raise awareness of the campaign and to inspire others to generate new ideas. This approach has already led to the launch of several environmental initiatives, including a competition that encourages customers to reduce waste and recycle.

Any business that buys Fullex locks in crates or pallets are challenged to upcycle the packaging. A £10 prize is awarded to anyone that enters, while the person with the best upcycling idea wins a £500 voucher for a high street store. To kickstart the initiative, UAP’s marketing director, successfully upcycled pallets into garden storage and planters, and the photos have been used as part of the promotional campaign.

UAP’s warehouse team has also developed a plan that will see bubble wrap replaced with more eco-friendly packaging and ‘waste walks’ implemented to identify areas of improvement.

David continued: “Our sustainability champions are playing a vital role in engaging employees in our S.E.E scheme and enabling every department to bring forward ideas that can make a tangible difference. To make sure these are viable, we set SMART (specific, measurable, achievable, realistic timely) targets and then closely monitor progress, ensuring there is sufficient resources to meet the objectives.

“Initiatives have been generated to help encourage a more sustainable way of thinking outside of the office too. We encourage our people to share the outcome of these measures with their colleagues to help motivate others to do the same.”

To share best practice, UAP has also asked its sales team to introduce ‘green customers’ to the business with a view to collaborate with them on new sustainability initiatives.

On a wider scale, the S.E.E. scheme is aiming to drive change across UAP’s manufacturing processes. The business is working with its suppliers in China to audit products and factories to stop the use of virgin plastic packaging.

Meanwhile, UAP’s technical services team has launched a long-term project aimed at replacing cold runner tools with hot runner moulds, which are used to produce plastic products and parts. The hot runner version provides a more sustainable solution, producing less waste and using less energy. UAP is working closely with suppliers to assess the full lifecycle costs of hot runner moulds to develop the most cost-effective options.

Reducing the company’s carbon footprint is another priority for UAP and forms part of the S.E.E. scheme.

“At director level, we are assessing our carbon footprint and putting measures in place to reduce energy use in the UK, China and India,” added David. “We already have solar panels on the factory roof in the UK and are refining policies across the business to help mitigate the impact of climate change. This is another area where we are engaging staff as even small changes can make a difference.

“As a long-term campaign with clear objectives, the S.E.E. scheme is already having an impact on our business, encouraging people at all levels to make positive changes. The ideas that are being developed will deliver consistent improvements and enable UAP to share best practice and knowledge, both internally and externally.”