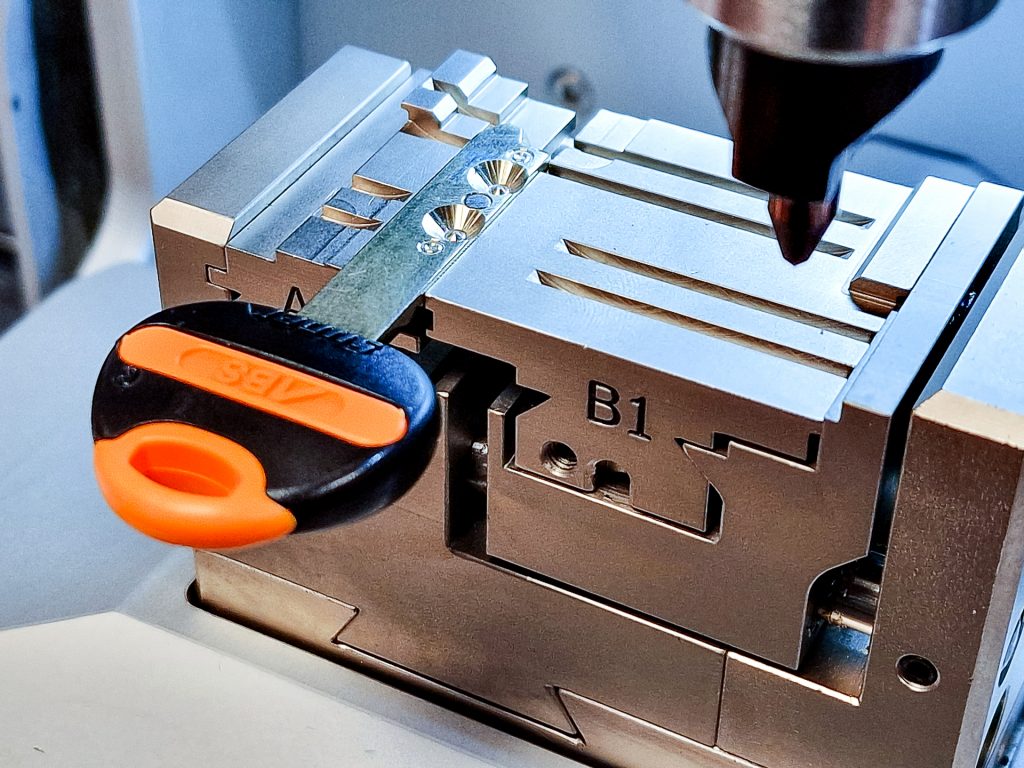

The workshop here at our head office in Berkhamsted is a very busy space. We can cut a wide range of keys here on site including basic cylinder, mortice and laser/dimple keys on our wide range of JMA key machines. These can be cut by copy or by manufacturers code by one of our experienced key cutters.

Cutting keys is not all we do, we also produce master suites from scratch, producing the pinning chart and then cutting and marking the differ keys. We can then assemble the cylinder after which they are all tested before being dispatched to our customers. One of our key machines the JMA AVANTCODE has an auto feeder which can hold up to 50 keys at a time and the cutting information can be put into the machine and then left to cut the keys without the need to load one key at a time which is a great time saver.

Master suites aren’t always on cylinders, and we quite regularly make up master suites for various applications on our IFAM range of unassembled padlocks as small as 40mm which don’t take a euro cylinder.

Some of the more popular orders that go through the workshop are keyed alike orders including all types of cylinders and mortice locks which aren’t an off the shelf product. Quite often one of the team is making up 50 sets of keyed alike mortice locks with additional keys ready for fitting to containers. They also make up lots of lever and detainer packs with keys to help reduce the cost of replacement locks for the locksmith to offer their customer.

Aaron White who is Technical Manager and his Workshop Manager Tony Johnson between them have over 75 years of Locksmith experience including all types of bench work and with the rest of the technical and workshop team have well over 100 years of key cutting experience, lock assembly and master suiting experience to call on.

After the workshop refit in 2022 we now have even more space for key machines and even a laser engraving machine we use for marking our master suite differ keys. This machine replaces or key stampers which not only makes the job quicker but also a lot quieter at great relief for everyone in the workshop. As well as our AVANTCODE we have four MULTICODES and a SUPRACODE which are all cutting keys for customer orders most of the day.

One of the more recent projects the Technical and Workshop team are involved with is the new range of GRAVOTECH engraving range of mechanical and laser engraving machines. Kevin Hardwick from GRAVOTECH spent two days in the office with various members of staff going through some of the machines that JMA will be offering to their customers. Luckily two members of the team already have experience with these machines, and they will be assisting the rest of the team and external Sales team with any enquiries they may have.

www.jma-uk.co.uk