With the spread of infection now at the height of concern, Karen Trigg of Allegion UK highlights how door hardware can lend a hand in helping to slow the spread of bacteria.

Bacteria and surfaces

Experts say that around 80 percent of infections are transmitted through the environment. Yet, in a detailed 2018 report conducted by Allegion UK, it highlighted that only 71 percent of healthcare facilities use environmental cleaning as a method to prevent the spread of infection. In addition, only 52 percent of the healthcare respondents believed their existing infection control measures to be robust and effective.

In addition to safe hygiene practices – including regular and thorough hand washing and surface cleansing, as well as the availability of anti-bacterial gel – decision makers can go one further and take extra precautions by investing in hardware preventatives, such as antimicrobial coatings, that are designed to keep the spread of bacteria to a minimum – especially in buildings that need it the most such as hospitals, schools and care homes.

How to handle cross-contamination

Under The Workplace (Health, Safety and Welfare) Regulations 1992 act, facility managers have a duty to keep inhabitants safe and their environments clean. Now, more than ever, it’s integral for decision makers to think of additional ways to keep their premises hygienic.

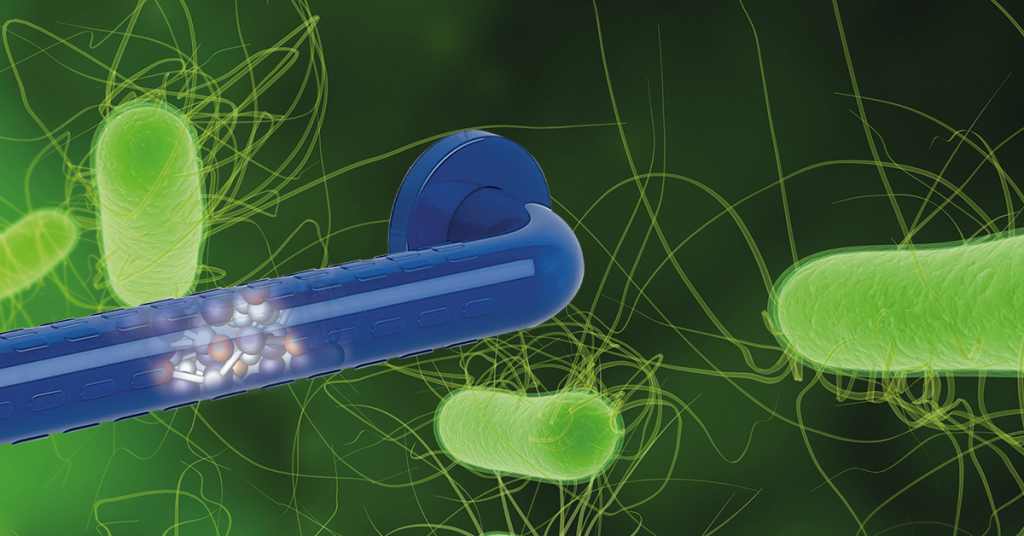

The first touch point for anyone entering, exiting or moving around a building is the door hardware, hence why it can be the most contaminated area. So for that extra layer of protection, decision makers can use tailored door hardware with inbuilt antibacterial properties. Antimicrobial coating for example, is specifically formulated to inhibit the growth of bacteria by interrupting cell multiplication and can go a long way in reducing the spread of bacteria.

Embedded within the nylon during production, anti-bacterial protection can’t be washed away or rubbed off. This provides effective and long-lasting defence, helping prevent germ build-up, and significantly reducing cross-contamination from contact areas.

Embedded within the nylon during production, anti-bacterial protection can’t be washed away or rubbed off. This provides effective and long-lasting defence, helping prevent germ build-up, and significantly reducing cross-contamination from contact areas.

Designed to provide immediate escape in an emergency, exit devices allow people to quickly leave a building without having to unlock the door. Again, some exit devices also include an added antimicrobial coating, which helps provide protection against the growth of bacteria and micro-organisms. Aside from aiding egress, these products are ideal for use in sterile environments such as operating rooms and cleanrooms.

Automating doors can also help to inhibit the spread of infection, especially in facilities with a high footfall. Automatic door sensors are used to activate operator devices fitted to the main access doors. In a surgery for example, these doors allow doctors and nurses to enter and exit the sterile area without touching any door handles or activation switches.

Investing in long-term door hardware products will help to protect your premises. And knowing that the premises is hygienic and cleaner will also help to improve staff satisfaction and productivity, leading to a well-organised, operated and efficient-running facility.

Invest now for a safer future

As a facility manager, it should be a continuous objective to ensure optimal health and safety for all people within your building(s). No matter the size of the premises, especially in the current climate, you should be confident that your facility is equipped to help prevent the spread of infection.

Although antimicrobial coating is not a substitute for good hygiene, by raising the standards of door hardware and infection control, we can fight the invisible threats more effectively. Not only will it help contain the spread of germs and bacteria, but taking this step will help to secure your premises and leave you well prepared for the future.